Hi guys

only my second post and ive come up with a design.

a brief description.

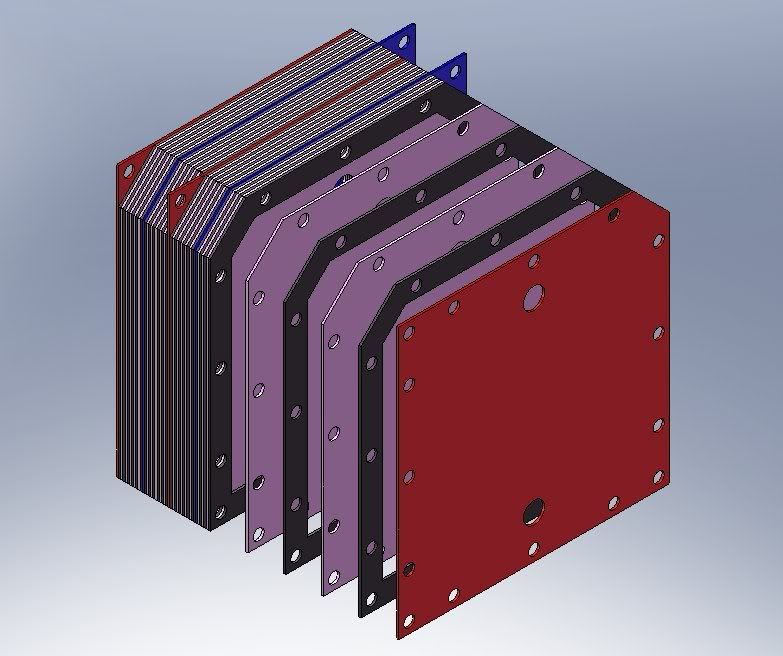

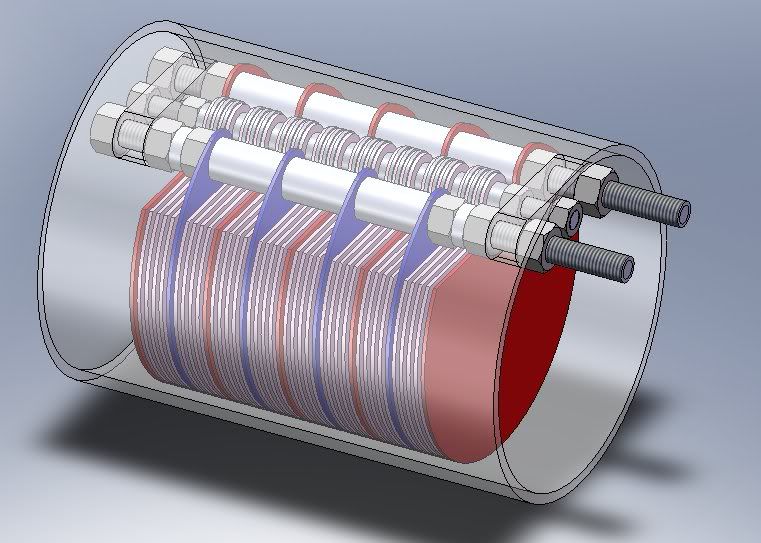

2 x M8 stainless screwed rod to hold negative and posative plates .

1 x M6 Stainless screwed rod to hold neutrel plates.

Acrylic boss to hold all the assembly together there will also be another one at the other end.

all nuts, washers and bosses to be make of stainless steel.

Pink plates are neutrel

Red are posative

Blue are negative

all plates are 316L 1.2mm stainless steel and to fit in a 4" tube

Please let me know your thoughts on it.

Gareth

Reply With Quote

Reply With Quote